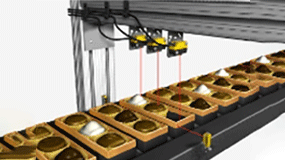

breakage detection

Wear and defects of drills not only affect the accuracy and speed of processing, but also lead to deformation and breakage of the material to be cut due to high temperature of drills, and even cause failure of the processing machine. In other words, the condition of the drill and its mastery is directly related to the ability of the cutting process. Therefore, to ensure the integrity of the drill bit, it is possible to use theSENPUM Slot Photoelectric Sensor SE-410 SeriesSensors with small to medium slot widths that are just right for the size of the drill bit are used to inspect the drill bit, which improves inspection efficiency.

.png)

GD GongAn Beian No. 44030502001756

GD GongAn Beian No. 44030502001756

Download

Download Delete all items

Delete all items